Folding Container House

.00

External dimension (mm) “5800 L * 2500 W * 2560H

Internal dimension (mm) 5660 L * 2360 W * 2350H

Folding state (mm) 5800 L * 2500 W * 430H

Total net weight(kg):1200

Payment Term: TT (30% deposit, 70% balance before delivery)

Delivery Time:10-20 days

Packing capacity: 10sets/40HQ

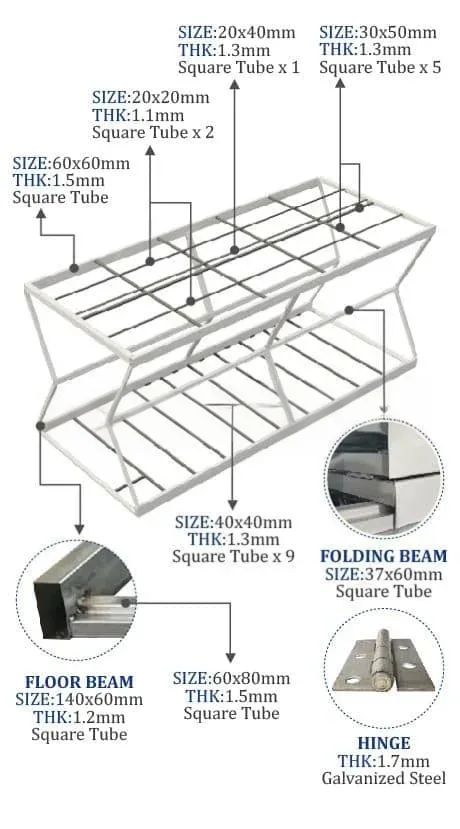

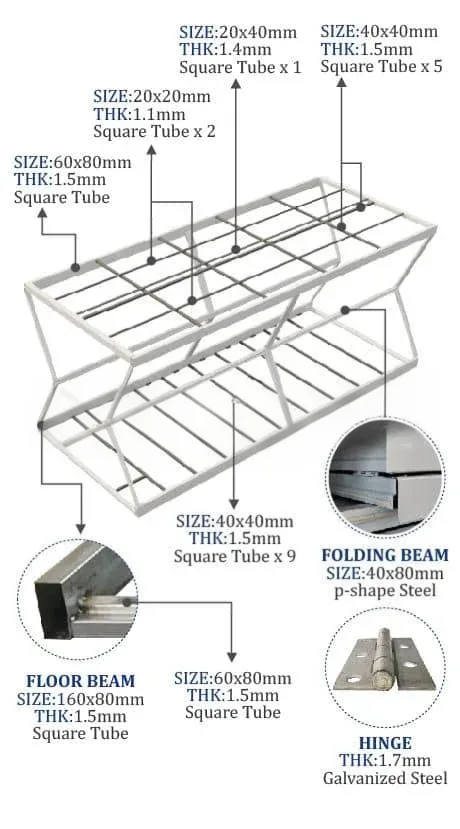

Main structure

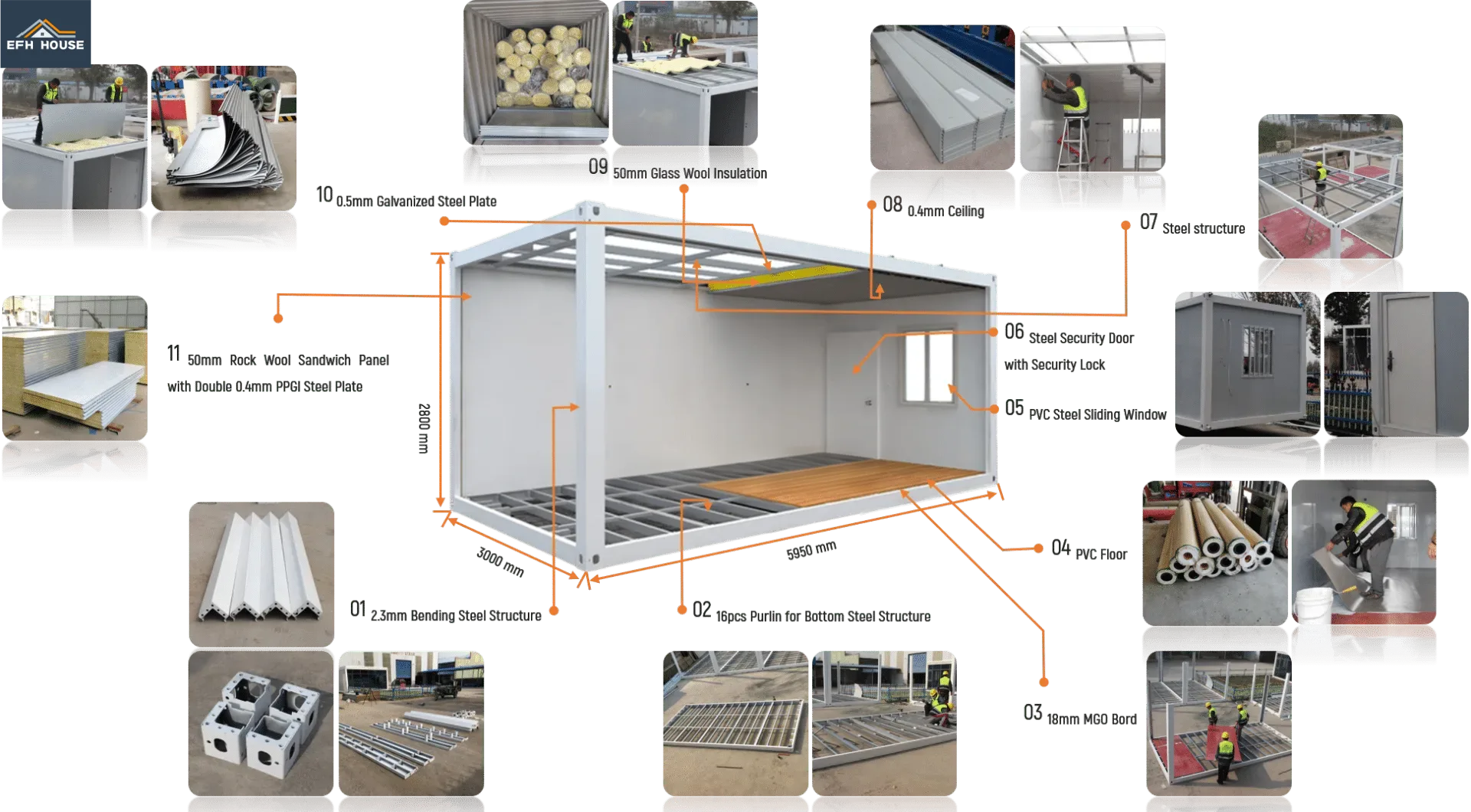

What is a foldable container house?

The foldable container house is a house that can be completed in the shortest time among all the current prefab houses, so for the places where the construction period is very urgent, or the labor is very expensive, a foldable container house is a perfect solution.

The advantages of the foldable house as below:

1. Low space occupancy

Because the foldable container can be folded for use, its space utilization rate is very good. It not only occupies a small area, but also has a lot of storage, which is much better than ordinary containers.

2. Easy installation and good quality

The foldable container can be built in a short amount of time. It is very fast and efficient, and its quality is very good. It can withstand the wind and the sun without affecting it.

3. Convenient loading and unloading

The foldable container is not only easy to install, but also easy to disassemble. The key is that it has a four-in-one function after being disassembled and folded, and the transportation is also extremely convenient.

4. Low cost

Although the cost of foldable containers is higher than that of ordinary containers, compared with the clutter and small output value of ordinary containers, the fixed costs of foldable containers are lower, the investment is large, and the income is high.`

What affects the folding container house price?

Our prefabricated folding container houses have different material options so we have different price levels for you. You can choose different thickness steel structure, different insulation material, different floorboard material, and even different types of door and windows. As long as you want to change it, we can achieve it for you.

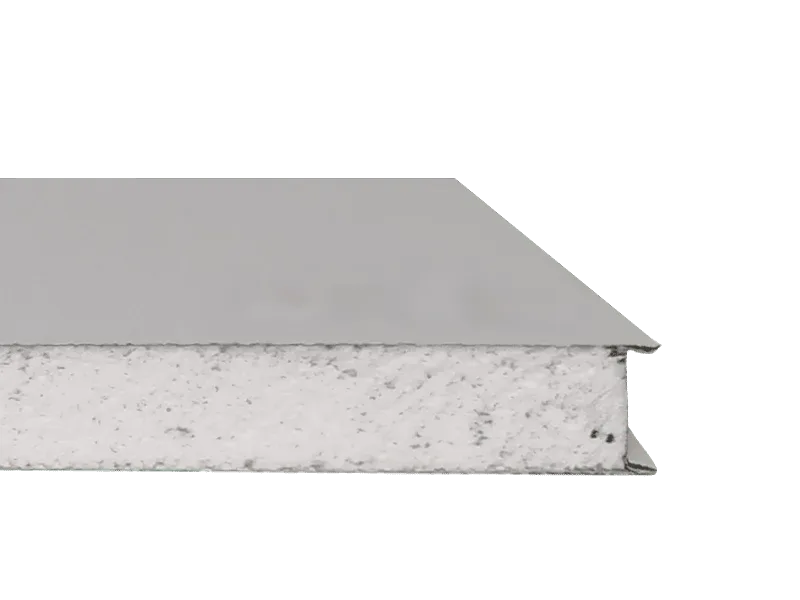

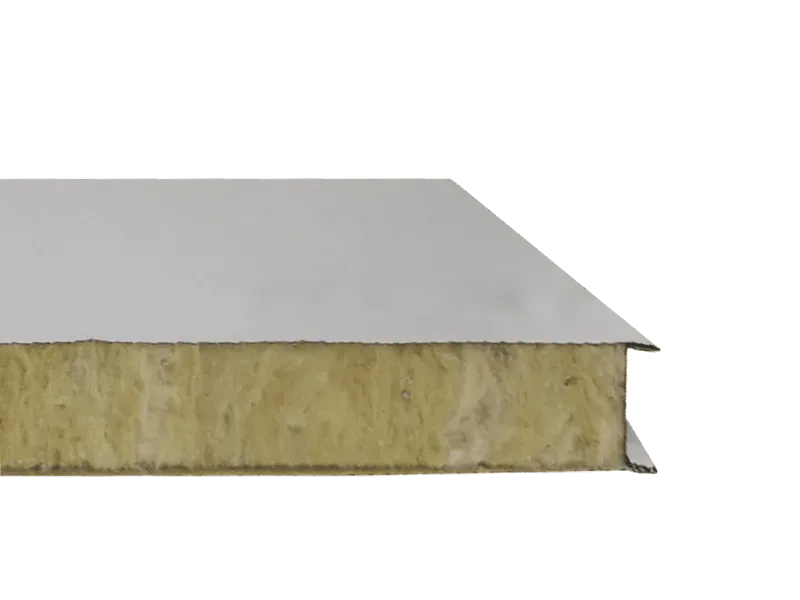

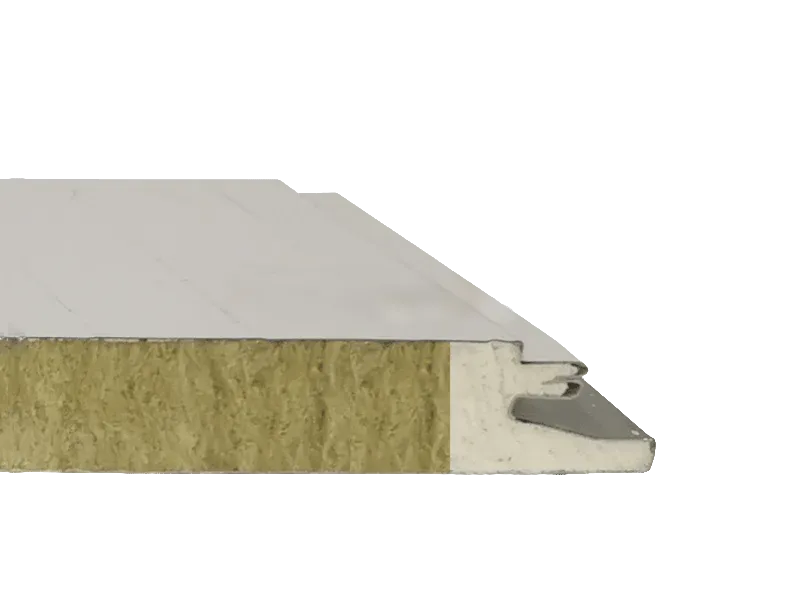

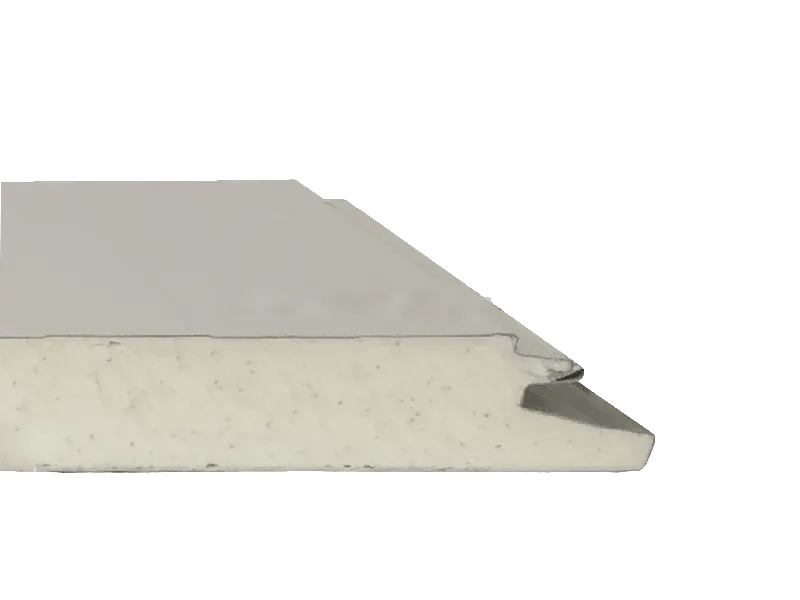

Different Sandwich Wall Panel

EPS sandwich and rock wool sandwich options can meet most using environments. If you have special requirements, PU sealed rock wool panel or PU panel can be recommended for your upgrade options.

Waterproof

Fireproof

Heat Insulation

Cost Effective

Sound Insulation

★ ★ ★ ★ ★

★ ★ ★ ☆ ☆

★ ★ ★ ★ ☆

★ ★ ★ ☆ ☆

★ ★ ★ ★ ★

★ ★ ★ ☆ ☆

★ ★ ★ ★ ★

★ ★ ★ ★ ☆

★ ★ ★ ☆ ☆

★ ★ ★ ★ ★

★ ★ ★ ★ ☆

★ ★ ★ ★ ★

★ ★ ★ ★ ☆

★ ★ ★ ★ ☆

★ ★ ★ ★ ☆

★ ★ ★ ★ ★

★ ★ ★ ★ ☆

★ ★ ★ ★ ★

★ ★ ★ ★ ★

★ ★ ★ ☆ ☆

Wall panel materials

| No. | Wall Panel Types | Thickness | Options |

|---|---|---|---|

| 1 | Rockwool Sandwich Panel | 50mm/75mm | the most cost-effective choice |

| 2 | PU Sandwich Panel | 50mm/75mm | high-end choice, better performance, more beautiful |

| 3 | EPS Foam Sandwich Panel | 50mm/75mm | the cheapest option, the shorter service life choice |

Steel Plate Colors

Please contact us to determine the color of the exterior steel plate and the material of the wall panel.

The commonly used steel plate colors are as follows:

| Structure | Components | Details |

|---|---|---|

| Specification | Length*width*height | External dimensions: length 5800mm*width 2500mm*height 2560mm |

| Internal dimensions: length 5620mm*width 2260mm*height 2440mm | ||

| Roof form | Roof form and material | |

| Folded state | 320mm (height) | |

| Net weight | 1160KG | |

| Drainage form | External drainage organization | |

| Number of layers | ≤2 layers | |

| Roof | External roof | 0.45mm cover steel plate + 40mm glass wool + ceiling steel plate 0.3mm |

| Internal suspended ceiling | 12 kg 50mm 0.326 Dongshang foam sandwich panel | |

| Insulation board | 8kg 50mm 0.236 foam sandwich panel | |

| Framework | T1.2mm special-shaped pass material Q235 | |

| Hanging head | T16mm Q235 steel plate | |

| Floor | Framework | Bottom side beam: t1.2mmQ235 galvanized steel pipe |

| End side beam: t1.2mmQ235 galvanized steel pipe | ||

| Beam: t1.2mmQ235 galvanized steel pipe | ||

| Bottom plate | T16mm magnesium oxychloride fireproof floor | |

| Side Panel | All outer/end plates | 8kg 50mm 0.236 foam sandwich panel |

| Framework | T1.2mm Q235 galvanized steel pipe | |

| Door | 1 exterior door | Steel frame; inner frame size: 977mm*2360mm |

| Window | / | 2*Aluminum alloy white unilateral sliding window, frame 930/1200mm |

| Folding Hinge | / | T3mm 180*76 galvanized hinge |

| Electrical System | / | Electrical wiring must be safe and concealed and installed in strict accordance with moisture-proof specifications. All electrical products must comply with CE certification and support European certification. |

| Technical Index | / | Voltage 220V, 50HZ |

| Circuit Composition | / | Connect the circuit according to the circuit engineering specifications. Indoor: wall socket. Light switch, LED light 2x16w. |

| Socket Distribution | / | Ceiling 16A three plugs*2, 10A five plugs with a switch at the front, one 16A air conditioning socket at the back, five plugs, and six. |

| Protective Coating | Overall framework | Electro-galvanized: zinc 10 microns; primer coating: zinc-rich 20 microns; topcoat: polyurethane topcoat 50 microns; total coating thickness: 80 microns. |

Playlist

0:28

0:39

0:37

0:39

Real Global Project

From intimate nooks to sprawling spaces, temporary installations to enduring structures—

Every creation stands as a wellspring of inspiration, ready to spark your imagination.

China Container House Manufacturer, Supplier

EFH is a manufacturer of prefabricated homes, container homes, and other products with over 10 years of experience. We have a factory in Bengbu, Anhui Province. Our materials meet national standards, offering earthquake resistance of magnitude 8, wind resistance of magnitude 10, and fire rating of Class A. They provide high safety features and spacious living spaces. We export to over 35 countries and regions worldwide, including Australia, South America, Europe, Africa, Asia, and the Middle East. Our products are certified by ISO 509001-2015, CE, and ASTM.

We are modular in design, easy to assemble and disassemble, and have superior performance. Within the box size range, the space design is rationally carried out according to the functional requirements. Based on the basic modules, it can be combined “at will” to meet various requirements of space and shape. The design is reasonable and adopts energy-saving, water-saving, material-saving and land-saving technical measures such as new energy, energy-saving lamps, centralized heating, household metering, grey water facilities, composite walls, sunshade and roof utilization, etc.

Furthermore, our container house has a service life of over 15 years.

It can be recycled without damage, is cost-effective, and is particularly suitable for secondary demolition and relocation projects.

The interior wall panels are metal, which is more stain-resistant than traditional building walls.

The stackable container house utilizes an advanced modular design and is factory-produced. The container is the basic unit and can be used individually or in various horizontal and vertical combinations to create spacious living spaces. Vertical stacking is possible.

It can be used for temporary dormitories and offices, tourism, car camps, exhibition halls, hotels, schools, shops, and more.

SEND A MESSAGE

Q: How About Your Delivery Time?

A: Generally within 15 days, it is according to the order quantity, partial shipment is allowed for big orders.

Q: What About The Installation?

A: We’ll provide the detailed installation drawing, supervisor guiding installation is available. We can do a turnkey job for some kind of project.

Q: Are you the factory or the trading company ?

A: Certainly, we are a factory and we can offer you a good price.

Q: What information should we offer before you quote ?

A: If you have the drawing, please give and tell us the material you use.If you don’t have the drawing, please tell us the size of the house. Then we design for you at a good price.